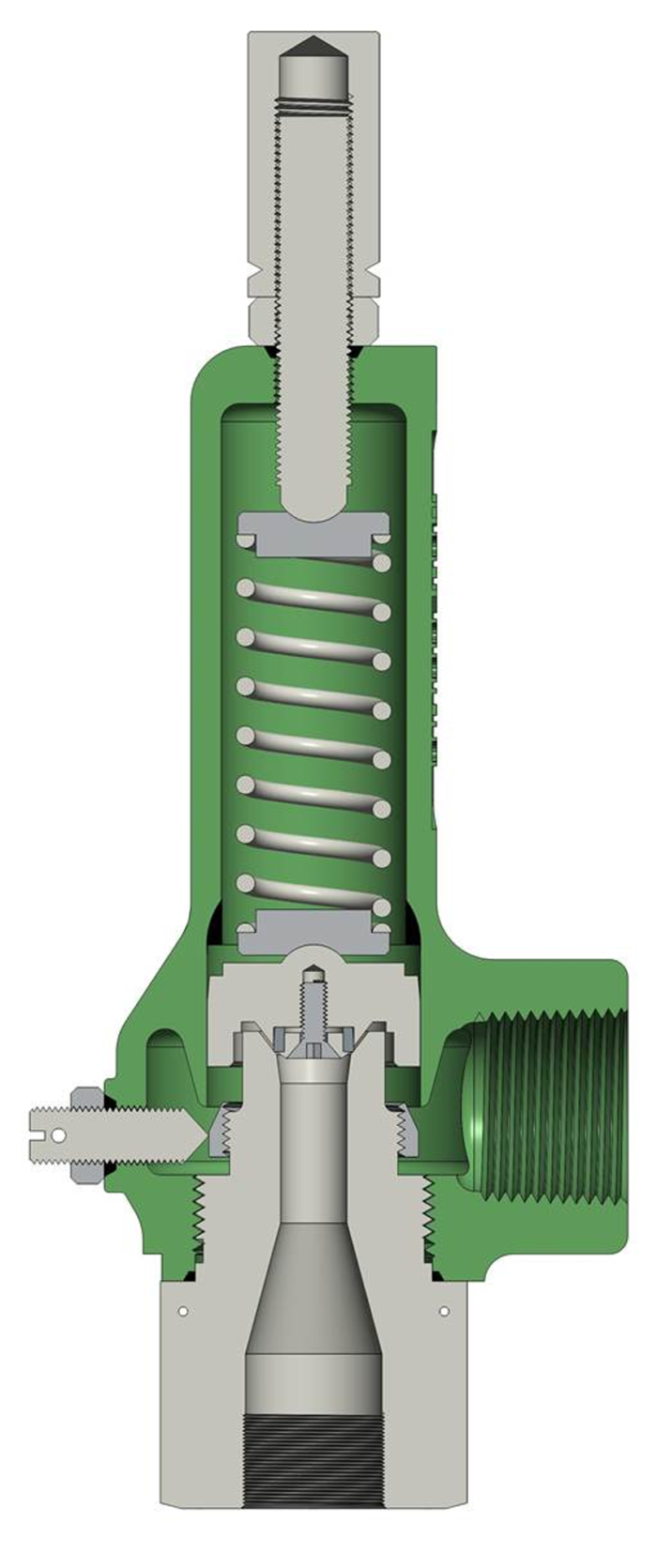

Direct Spring, Conventional

F84M / F84 (Plastic Seated): Gas & Vapor Service

Enhanced performance conventional style SRV’s. Made in accordance with ASME Section VIII or “CE” mark. Available in brass, carbon, and stainless steel materials as standard. Special alloy construction available upon request. A variety of seat materials and connection styles available. F80M series small orifice devices are ideal for instrumentation panels, line blocks on cryogenic storage tanks, or thermal relief applications.

FEATURES

- Spring-operated, snap-acting

- Soft seated (Plastic)

- Full lift at set pressure

- Bubble tight seating and re-seating

- Adjustable blowdown

- Integral / full nozzle, corrosion resistant trim

- Packed lift lever available on most sizes

- Unbalanced against backpressure

APPLICATIONS

- Compressors

- Thermal relief / instrument panels (see F84M Series)

- Storage Tanks

- Air/gas equipment or processes

- Flashing cryogenic fluids

Service Envelope

| Connection Sizes Larger sizes available on request | ¼” x ½” – 2” x 3” (6mm x 13mm – 50mm x 75 mm) |

| Set Pressure Ranges See F80 Catalog for orifice specific ratings | 15 – 9,944 psig (1.03 - 685 barg) |

| Temperature Ranges | -423 to 525°F (-252 to 274°C) |

| Orifice Area Range | .003 – 1.689 in2 (1.9 – 1089 mm2) |

| End Connections Custom types available on request | Threaded: NPT, SAE, MS33649/AS5202, AN 37° Flare Welded: ASME / DIN / API / SAE flanged, Grayloc Specialty: Swagelok® Tube / VCR, Threaded & Coned |

| Materials of Construction Custom available for service or on request | Carbon Steel, Stainless Steel, Brass, Monel, Hastelloy C / C22 / C276, Duplex 22% or 25% Cr |

| Seat Materials Custom available for service or on request | Plastic: Teflon®, Ekonol-filled PTFE, Kel-F (PCTFE), PI/PAI (Vespel®, Duratron®, or equal), PEEK |

CERTIFICATIONS & COMPLIANCE

- ASME Sec VIII Div. 1 (NB-18 Cert. No. 28066)

- API 520 (Sizing & Selection of PRV’s) / API 527 (Seat tightness of PRV’s)

- Superior flow capability (KA factor) vs. equivalent API 526 orifice

- API 526 center-to-face dimensions available on most sizes

- NACE MR0175 H2S compliant materials available on request

- PED / CE (2014/68/EU)

- Canadian CRN (all Provinces per CSA B51)

- ABS Product Design Assessment (Cert. No. 15-HS1393800-PDA)

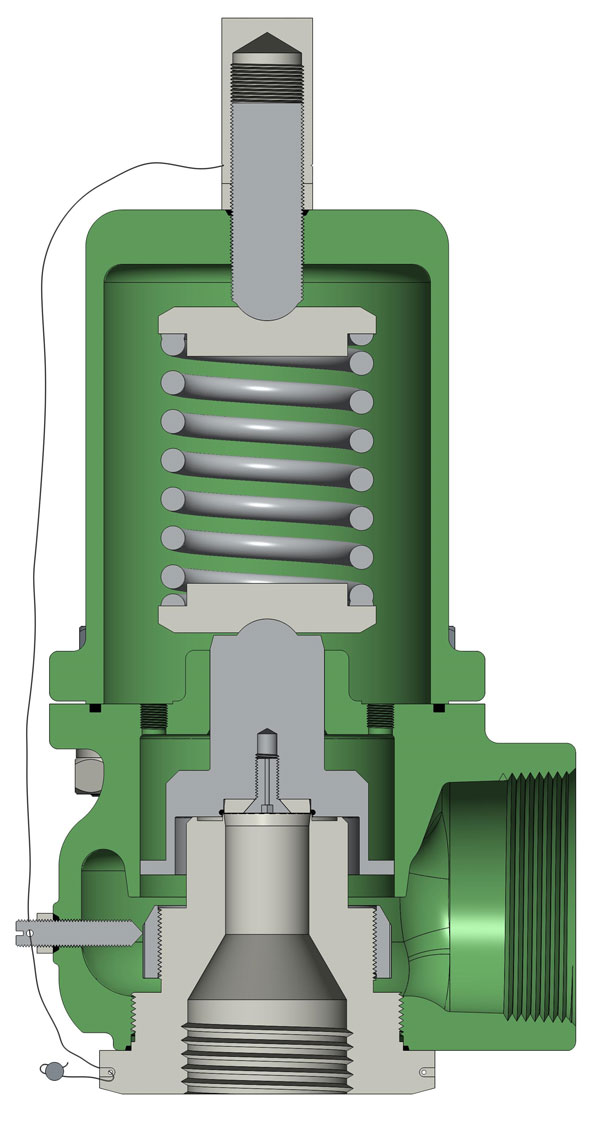

F85M / F85 (Elastomer Seated): Gas & Vapor Service

Enhanced performance conventional style SRV’s. Made in accordance with ASME Section VIII or “CE” mark. Available in brass, carbon, and stainless steel materials as standard. Special alloy construction available upon request. A variety of seat materials and connection styles available. F80M series small orifice devices are ideal for instrumentation panels, line blocks on cryogenic storage tanks, or thermal relief applications.

FEATURES

- Spring-operated, snap-acting

- Soft seated (Elastomeric)

- Full lift at set pressure

- Bubble tight seating and re-seating

- Adjustable blowdown

- Integral / full nozzle, corrosion resistant trim

- Packed lift lever available on most sizes

- Unbalanced against backpressure

APPLICATIONS

- Compressors

- Thermal relief / instrument panels (see F85M Series)

- Storage Tanks

- Air/gas equipment or processes

- Lite molecular weight gases (H2, He)

Service Envelope

| Connection Sizes Larger sizes available on request | ¼” x ½” – 2” x 3” (6mm x 13mm – 50mm x 75 mm) |

| Set Pressure Ranges See F80 Catalog for orifice specific ratings | 15 – 9,944 psig (1.03 - 685 barg) |

| Temperature Ranges | -423 to 525°F (-252 to 274°C) |

| Orifice Area Range | .003 – 1.689 in2 (1.9 – 1089 mm2) |

| End Connections Custom types available on request | Threaded: NPT, SAE, MS33649/AS5202, AN 37° Flare Welded: ASME / DIN / API / SAE flanged, Grayloc Specialty: Swagelok® Tube / VCR, Threaded & Coned |

| Materials of Construction Custom available for service or on request | Carbon Steel, Stainless Steel, Brass, Monel, Hastelloy C / C22 / C276, Duplex 22% or 25% Cr |

| Seat Materials Custom available for service or on request | Plastic: Teflon®, Ekonol-filled PTFE, Kel-F (PCTFE), PI/PAI (Vespel®, Duratron®, or equal), PEEK |

CERTIFICATIONS & COMPLIANCE

- ASME Sec VIII Div. 1 (NB-18 Cert. No. 28066)

- API 520 (Sizing & Selection of PRV’s) / API 527 (Seat tightness of PRV’s)

- Superior flow capability (KA factor) vs. equivalent API 526 orifice

- API 526 center-to-face dimensions available on most sizes

- NACE MR0175 H2S compliant materials available on request

- PED / CE (2014/68/EU) compliant on request

- Canadian CRN (all Provinces per CSA B51)

- ABS Product Design Assessment (Cert. No. 15-HS1393800-PDA)